Article: Conewago residents fear becoming “Conowaste”

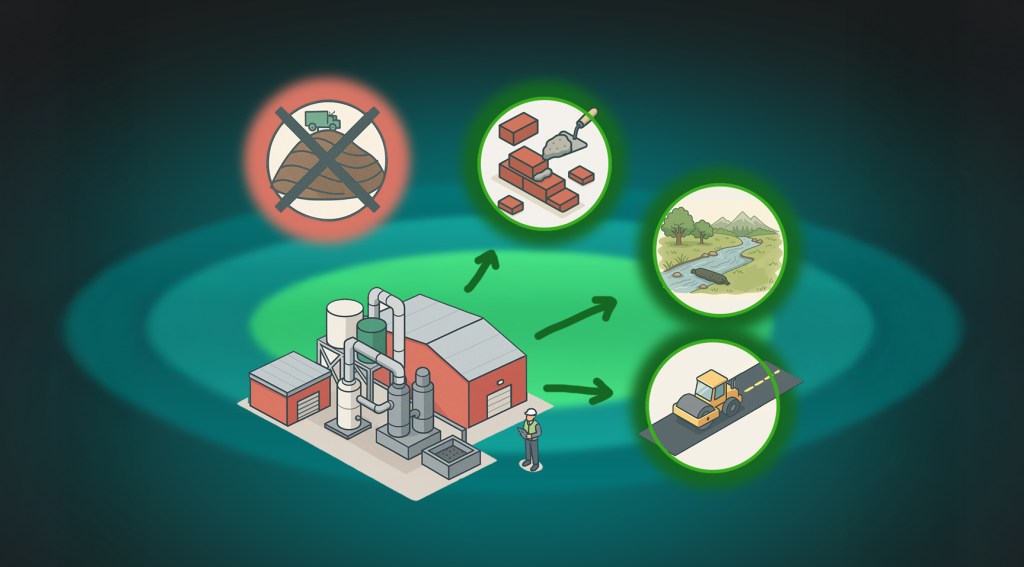

Conewago Township supervisors addressed early questions surrounding a potential Earthcare Solutions bio-waste processing facility at their first meeting of 2026, emphasizing regulatory oversight, environmental standards, and coordination with neighboring municipalities as the review process moves forward. Click the link below to read the full article